Company Presentation - Cochin Special Economic Zone and 100% Export Oriented Unit

"WE are here for the sake of

HUMANITY,

So

We have started this venture to support our Research Team"

Our 1st Manufacturing Plant

Capacity -5000kg/day

Investors

We respect Investors

because

We Would like to develop

Brain Chamber The HOP The hall of polymers

AIM - Will be $100 million USD company in 2.5 years.

We are looking for INVESTORS

for Investment details

Mail : uday@brainchamber.net

Site :thehallofpolymers.com/

NOW,

Lets Come to the Technical details

1. Extruders (PP / HDPE Stretching Lines)

The blends of PP granules, M/B and filler compounds are supplied as raw materials to the Extruders. These granules upon melting are filtered from screen changer. The PP film further forms a die which is then quenched making the film split into tape. This tape is further stretched in hot air oven followed by the chilling process. Tape winding process is then carried out using bobbin winders after which the bobbins formed are checked and cleaned.

Features :

• Very Fine Quality of Yarns

• High Flexibility to produce different kind of coloured yarns

• European design technology

• Make : Lohia

• Capacity : 250 KG/ HRS.

/2.%20looms.png)

2. Circular Weaving Machine

The process of fabric weaving into looms is done in the circular weaving machine. The rolls obtained are cut, checked and stocked here.

The new generation circular weaving machine with six shuttle is designed to weave fabric suitable for a variety of applications like plastic granules/fertilizer/chemicals and smaller covering fabric/tarpaulin etc. Additionally, these machines have an option to produce Anti-slip fabric on special request.

Features :• Type : Circular weaving machine

• Make : GCL

• 6-shuttle: 80 looms

• Capacity : 200000 meter/day

3. Lamination

We use high-technology laminating machines for woven fabric, cement bag, jumbo bag, EVA and tarpaulin. The unwinder and rewinder are driven by semi-automatic tension control. These laminating machines have turret unwinder for unwinding plastic film and metalizing film.

Features :• Make : GCL

• Width of dye : 1800 mm

• Capacity : 180 kg/hr

• Type : Turnbar

/4.%20cutting.png)

4. Cutting and stitching machine

Cutting of the printed fabrics into pieces is done in the cutting and stitching machine. These pieces are further checked and sort. These sorted fabrics are given for valve forming process. The printed fabrics are then stitched from the bottom to form bags.

We use latest model of cutting and stitching machines made by GCL. The new age machine cuts, bottom folds and stitches the bags or sacks. The complete processing is done just from the tubular fabric roll. These machines can carry operations like counting, stacking and conveying.

Features :• Make : GCL

• Type: Cutting and Stitching Machine

• Capacity : 3000 Bags/Hrs.

5. Printing

We use multipurpose flexographic 3 colour printing machines for better print quality and clarity. These machines are equipped with statistically and dynamically balanced rolls and the gears of hobbing cut. The infeed and the outfeed system of the machine maintain constant tension of fabric for better print registration.

Features :• Turret unwinder with online manual splicing

• Efficient and advanced auto tension control system and unwinder

• Inline perforating unit

• High frequency IGBT corona treater

/6.%20bailing.png)

6. Hydraulic Bailing Press For HDPE/PP Bags

The hydraulic bailing press is used for pressing PP/HDPE bags to minimize the volume for convenient packaging & transporting. These machines are designed for free shift operation and can produce different pressure as per the requirement.

Features :• Compact hydraulic block

• Overload protection valves

• Push button operation

• Preset bale height table auto stop

• Pressure regulator and gauge

• Emergency brake

7. Rewinder Machine

We use high technology semi automatic rewinder machine. It customizes size and does palleting of EVA fabric.

Features :• Make: Customized

• Size of pallet: as per client requirement

• Capacity: 40,000mtrs/day

Power Consumption

Name Total Power Tape Plant =1 272.92KW Looms =15 100KW Lamination =1 100KW Cutting=1 5KW Printing=1 3KW Baling Press=1 8KW Total= 488.92KW

Processing cost

1. Cost of raw material = Rs. x

2. Machinery cost = 11.5% of x.

3. Energy cost = 1.75% of x.

4. Labour = 3% of x.

Now,Manufacturing cost would be,

y = x + Processing cost.

Thus,Profit (z) = y + 15% of x.

Turnover/day (z) = Rs. 8, 75,000/day.

= 14,000 $ USD/ day

Turnover/month = Rs. 2, 62,50,000/month.

= 4,20,000 $ USD/month.

Annual turnover = Rs. 31,50,00,000/year.

= 50,40,000 $ USD/year

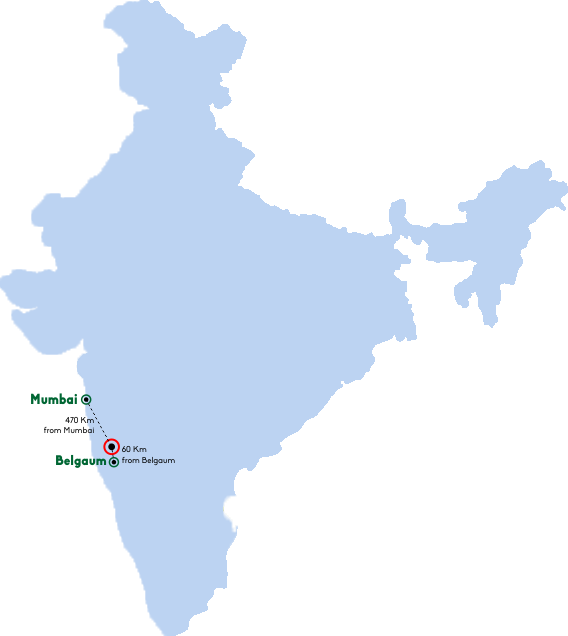

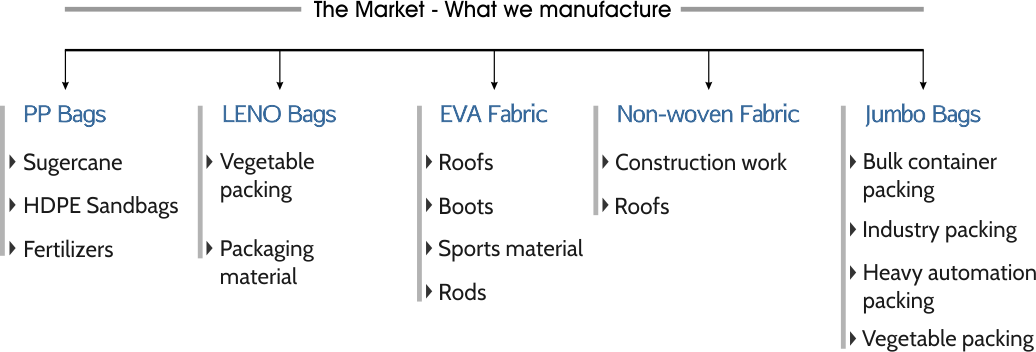

Marketing

"We Support to EVA / NonWoven / JumboBags World Wide"

We Hold Below Website

- The Hall of Polymers - www.thehallofpolymers.com

- Brain chamber Polymers - www.brainchamberpolymers.com

- Jumbo Bag Manufacturing - www.jumbobagsmanufacturing.com

- Jumbo Bag Suppliers - www.jumbobagmanufacturing.com

- jumbo Bags Exporters - www.jumbobagsexporters.com

- Jumbo Bags India - www.jumbobagsindia.com

- jumbo Bags Association - www.jumbobagsassociation.com

- Non Woven Manufacturers - www.nonwovenmanufacturers.com

Our Financial Window

WE HAVE THE BEST FINANCE TEAM to do the critical valuations on real time. This also gives the clarity to our INVESTORS in real time

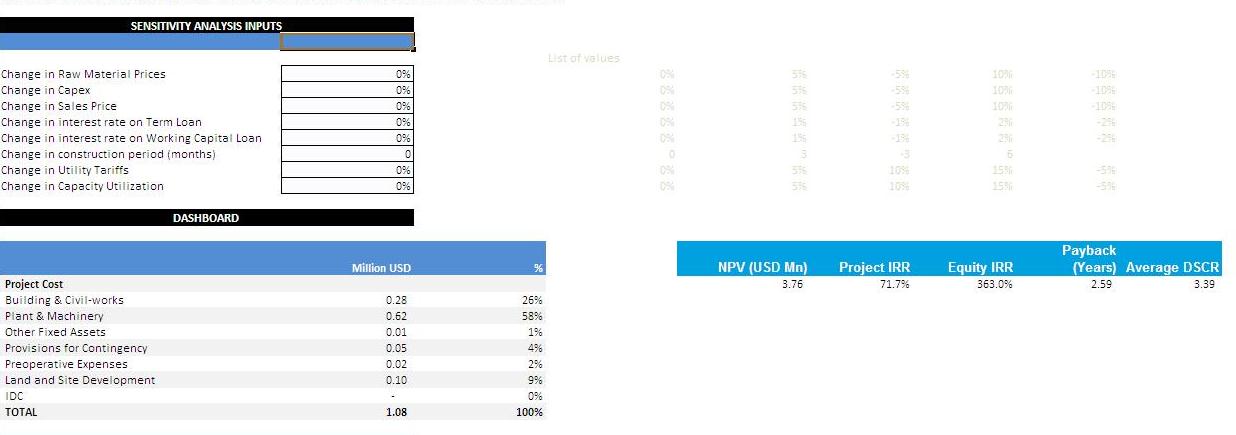

The Financial Dashboard depicts the Sensitive analysis of the inputs and the total cost of the Project.

Future targets of the company in the coming decades are analysed in the above window.

Our Commercials

Production Capacity 5000kg/Day

Monthly turnover

420000 $USD

Annual turnover

5040000 $USD

Profits

Gross Profit/yr= $1.4 Million USD

Net Profit/yr= $1 Million USD

/1.%20extruder.png)